Welcome to Bantry Metal Products ltd.

-

Quality Metal Products & Services for Over 40 Years

Bantry Metal Products is a full service steel and metal fabrication company catering to industrial, governmental, and residential projects within north america. We offer extraordinary talent, craftsmanship, and state of the art equipment to complete any project or task requested, on time with quality, accuracy, and professionalism. Bantry Metal Products proactively seeks, researches, and acquires equipment to fulfill industry demands such that we can continue to improve and offer quality product to our clients with precision and competitive prices as we have since 1976.

Featured Services

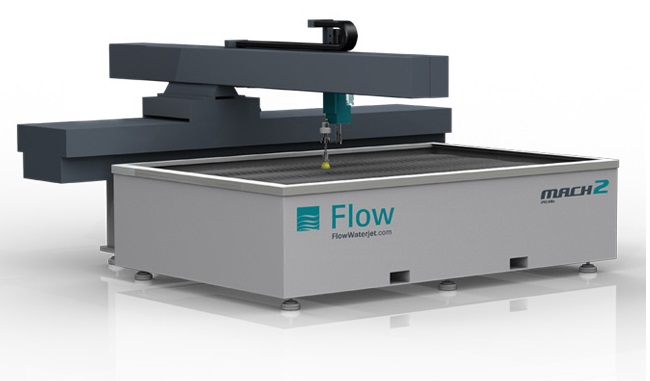

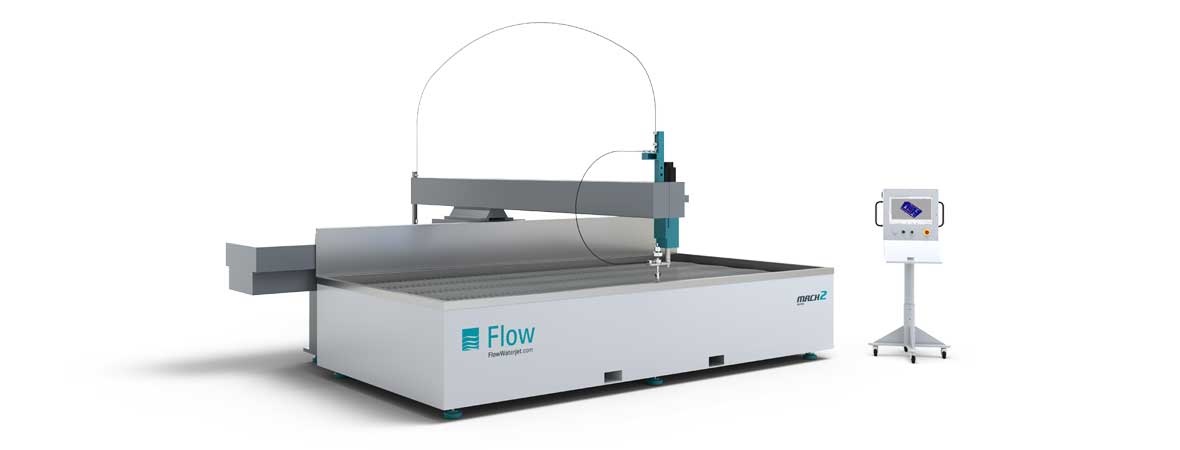

Flow Jet

Because there is absolutely no mechanical stress, heat distortion or heat-affected zone (HAZ), secondary processing can usually be eliminated. Get a satin smooth edge directly off the waterjet table.

Metal Forming

Forming, or metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged.

Metal Punching

Punching is a metal forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. The punch often passes through the work into a die.

Metal Shearing

Shearing is a process which cuts stock without the formation of chips, burning or melting. In technical terms, the process of "shearing" involves the use of straight cutting bladesorm of sheet metal or plates.

Metal Rolling

Rolling is a metal forming process in which metal stock is passed through 2 rolls to reduce the thickness and to ultimately make the thickness uniform. Rolling is classified according to the temperature of the metal rolled.

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

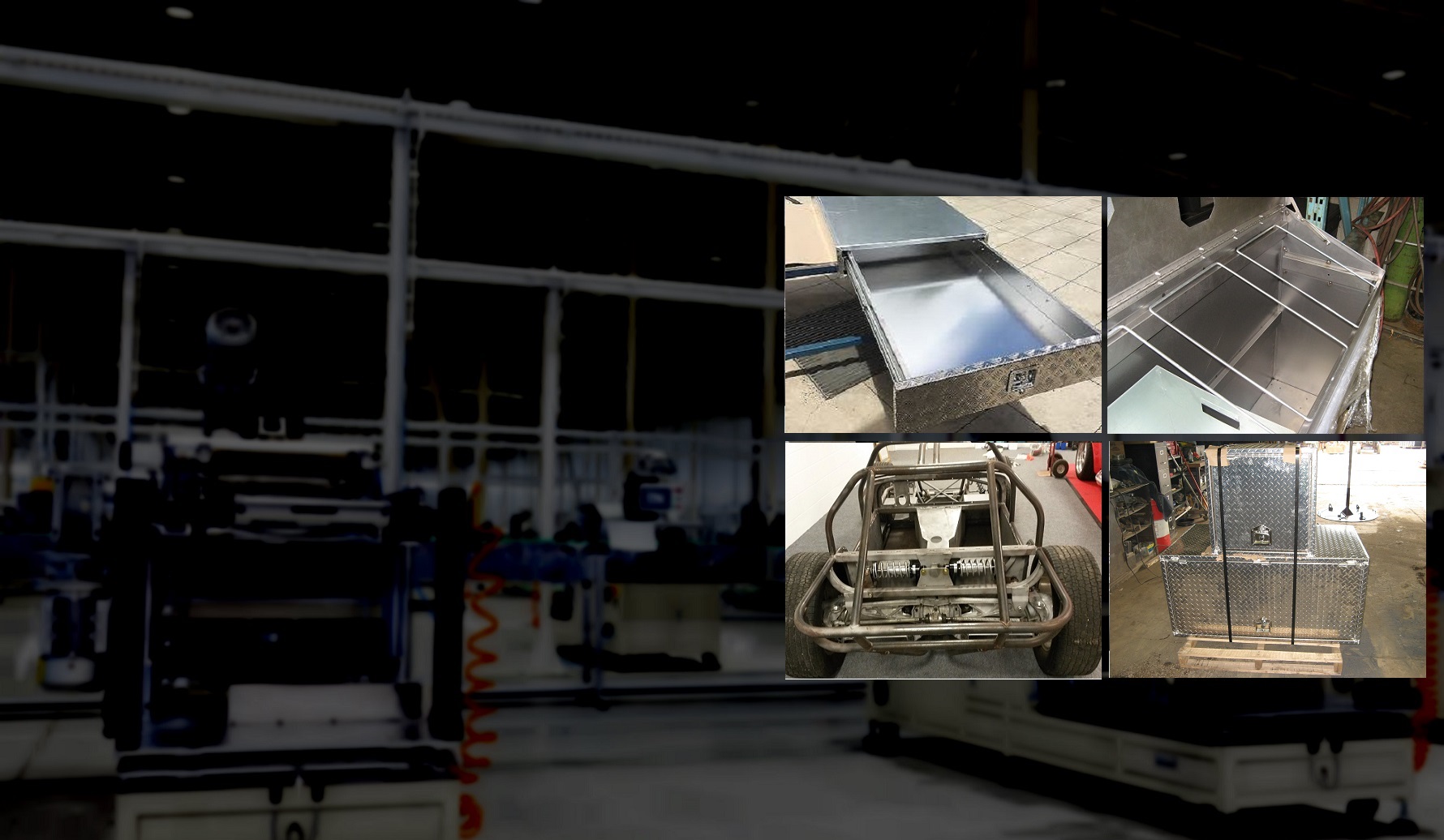

Mini Gallery

Flow Mach 2 Waterjet

Bantry Metal Products is pleased to announce the introduction of the state of the art flow mach 2 waterjet to our customer metal fabrication line up. The Flow Mach allows for precision cutting with tolerances near 0.005, resulting in a product with clean smooth edges. The need for secondary finishing becomes obsolete.

Some of OUr CLients

Machines & Tools

-

LINCOLN ELECTRIC TIG MACHINE SQUARE WAVE #355 handles all materials

-

LINCOLN ELECTRIC PRECISION TIG #375 handles all materials

-

LINCOLN ELECTRIC MIG WELDER #FL-72 welds any thickness of Steel

-

CANOX MIG WELDER #C-DW-450 welds any thickness of Steel

-

LINCOLN ELECTRIC POWER MIG #300 welds any thickness of Aluminum

-

FLOW MACH 2 WATER JET Precision cutting with a tolerance near 0.005, any material - no need for secondary finishing

- PLASMA CUTTER hand cutter, cuts all materials up to 1” plate

-

AMADA C&C PUNCH PRESS 9 tool station machine with a 360 degree auto index, 60 x 120” long and 1/8 thickness max, will also punch Stainless at 1/8 max

-

HOBART RC 200 MIG WELDER all material, any thickness

-

BAILEIGH INDUSTRY ROTARY DRAW TUBE BENDER bends to form pipe ¾ diameter - 3” diameter

-

DRILL PRESS x 3

-

GEKA HYDRACROP 110/S IRON WORKER punches 3/8 – 1 ½ diameter and shears ½ x 12” flat bar

-

SPOT WELDER tolerance is thinner gauge, welds Steel & Stainless only

-

FAMAR Rolling machine, 6” diameter rolls, 10 ft long rolls and 1/8 max thickness

-

TAURING MACHINE STRUCTURAL STEEL ROLLER 3 x 3 square tube, 3 x 3 angle & 3” flat bar

-

EUROMAC NOTCHER # MULTI 220/6 notches corners, forms small angles and bends ¼ max

-

PEIRCE ALL SINGLE STAGE PRESS Steel up to 3/8 max, Stainless up to ¼ max, Aluminum up to ½ max and punches holes up to 5” max

-

MARVEL BAND SAW cuts 12 x 12 square tube, 12” flat bar, handles all material and any thickness

-

ALLSTEEL 10FT SHEAR handles 3/16 mild Steel max, ¼ Aluminum max, 1/8 Stainless max

-

WYSONG 12 FT SHEAR #1238CNCB shears 12 ft long at 3/8 max of mild Steel, shears 12 ft long at ½ max of Aluminum, shears 12 ft long at 3/16 max of Stainless

-

WYSONG HYDRAULIC 250 TON BRAKE PRESS 12 ft bed CNC Programmable, ½ x 2 ft long max, bend tolerance 3-5 thousands of an Inch

-

WYSONG HYDRAULIC 50 TON BRAKE PRESS 5 ft bed CNC Programmable, ½ x 2 ft long max, bend tolerance 3-5 thousands of an Inch

-

SAMPSON 6 FT ROLLER 6” diameter rolls, ½ x 12” flat bar max

7130 Pacific Circle,

7130 Pacific Circle,